Fascination About Dust Extractor Vs Shop Vac

Wiki Article

The 7-Minute Rule for Dust Extractor Vs Shop Vac

Table of ContentsUnknown Facts About Dust Extractor Vs Shop Vac3 Simple Techniques For Dust Extractor Vs Shop VacNot known Details About Dust Extractor Vs Shop Vac Getting My Dust Extractor Vs Shop Vac To WorkEverything about Dust Extractor Vs Shop Vac

Prior to the growth of dirt collection systems, dirt explosions, particularly in woodworking stores, were really usual. The issue was so widespread that lots of stores had a wall available to the exterior. Similar to fire prevention, dirt collection systems maintain air moving as well as flowing to protect against the possibility of dirt accumulating completely to produce a surge bubble.

Dirt collection systems may get confused with air conditioning, they have far extra benefits. Odor reduction is not common in all dust collection systems.

Dust Extractor Vs Shop Vac - The Facts

Offense of these criteria can bring about a company being closed, which makes it necessary to install an acceptable dust collection system. Something that is rarely considered in a commercial setting is the tidiness as well as top quality of the floor. One of the benefits of a dirt collection system is the elimination of the demand to frequently clean up the flooring.

Compliance with government regulations is the most vital of all the encouraging variables for mounting a dust collection system. Business that do not have the appropriate particulate percentage can be fined or forced to discontinue operations. OSHA and also NIOSH very closely check possibly dangerous working conditions and also do random examinations. A dirt collection system is crucial for any kind of market that generates gasses, dirt, overspray, or other forms of particle matter.

More About Dust Extractor Vs Shop Vac

Most of the procedures that make use of dust collection systems are mainly worried concerning security given that several procedures involve using gasses. Plasma cutters generate great smoke and fumes, which need to be gotten rid of to shield the driver. Dust collection systems for plasma cutters make use of particularly created downdraft tables to draw the fumes away from the work area and also employees.Various types of dust collection systems are utilized to record and collect the dangerous issue generated by welding. Since welding pop over to these guys fumes as well as dust can be eruptive, the product generated must be checked for its fire and also eruptive characteristics based on the requirements of OSHA and the National Fire Defense Organization's, Organization (NFPA).

The volatility of the dirt from seed and also grain procedures is so high that OSHA has a collection of criteria especially created for these procedures. dust extractor his explanation vs shop vac. Dust from seed and grain operations differs according to the kinds of materials being relocated.

Dust Extractor Vs Shop Vac Things To Know Before You Get This

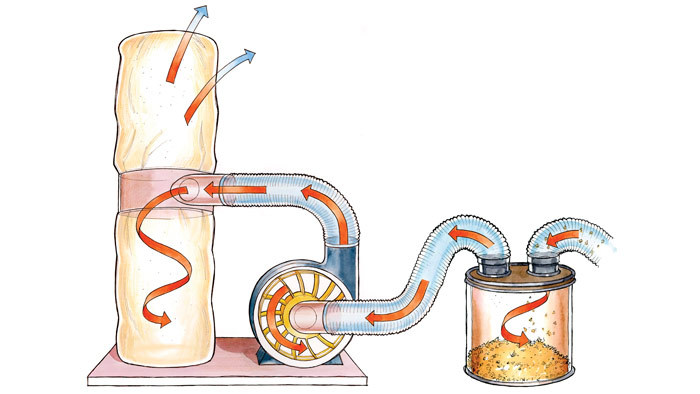

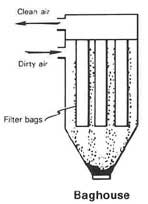

Baghouse enthusiasts are utilized for their high efficiency of 99% and also dependability. The initial problem for air top quality in the workplace began with woodworking since it produces huge volumes of sawdust and also fumes. As producers have actually examined the various woodworking procedures, they have discovered that a wide range of particulate matter is produced.Lumber mills and also sawmills require different dirt collection systems than wood pellet manufacturers. Each sort of operation calls for a different type of collection system. No matter the sort of woodworking procedure, wood dust has actually been discovered to be the significant cause of dirt accidents. The risks of dirt from woodworking operations are extremely ignored.

Both kinds of click for info dust collection systems for woodworking procedures are cartridge and baghouse, with baghouse being one of the most reliable. No matter the sort of system selected, it needs to be created and engineered to particularly fit the operation as well as manufacturing procedure of the consumer. The main concern for dust collection systems in the food processing market is transportation, storage, and also blending, which are the locations that accumulate the most dust.

6 Simple Techniques For Dust Extractor Vs Shop Vac

Filtration systems can be connected to all tools as well as locations. The 2 agencies that regulate air top quality for mining operations are the Environmental Protection Agency (EPA) and also the Mine Safety and Health And Wellness Management (MSHA), a branch of the Division of Labor.Dust control systems for mining procedures should withstand heavy usage yet be versatile enough to adapt to a wide array of problems. The nature of mining dirt requires really durable and also trustworthy tools because mining dust can be rough as well as abrasive in addition to extremely fine. The different kinds of mining determine the sort of dirt collection system (dust extractor vs shop vac).

No matter the procedure, mining dust control systems are developed to suppress explosions, isolate fumes, as well as control smells from gasses. The typical sorts of dirt collection systems for mines are baghouse and cartridge. Fiberglass dirt is a significant wellness risk that can cause eye, skin, and lung inflammation. The dimension of the dirt bits differs depending upon the kind of operation, with particular materials having the potential to combust.

Report this wiki page